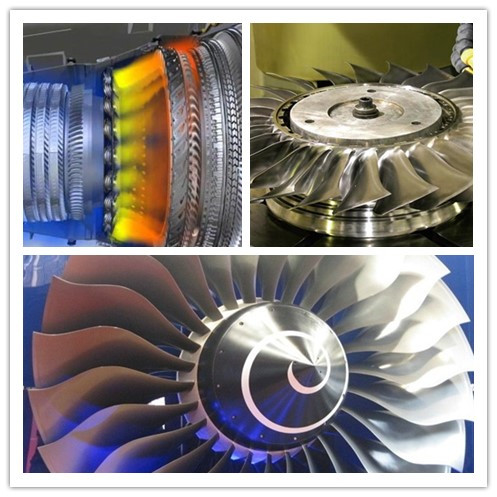

The final forming of aviation blades has always been a bottleneck technology in aviation engine manufacturing, and the research on automatic polishing technology of blades can solve a series of problems caused by manual polishing of domestic blades. At present, the technical difficulties in polishing aviation engine blades include the following main aspects:

(1) Uneven surface machining allowance. Precision forged titanium alloy compressor blades generally use surface positioning and then tenon machining. This machining feature causes uneven surface machining allowance due to benchmark conversion when using tenon positioning for surface polishing. At the same time, the profile is affected by residual stress and there is deformation, especially for compressor blades. The magnitude of deformation is the same as the thickness of the inlet and exhaust edges of the blades, reaching over 0.1mm.

(2) The curvature radius of the blade inlet and exhaust edges is extremely small. Some small compressor blades may even reach the R 0.1mm level. This makes it necessary to use a very small contact force for grinding the inlet and exhaust edges of the blades. In addition, when grinding the intake and exhaust edges, the edge heat dissipation conditions are not good, and the intake and exhaust edges of the blades are prone to erosion.

(3) The shape of the transition arc is complex and the radius is very small. In the process of blade design, the transition arc is formed by a smooth transition between the flow channel surface and the blade body surface, with a rounded corner of around R 2mm and a significant change in curvature, which brings great difficulties to programming. Whether using grinding wheel grinding or abrasive belt grinding, the grinding wheel or abrasive belt clamping wheel must be less than φ The development difficulty and service life of 4mm grinding wheel or belt clamping wheel are facing great challenges.

The data information of the blade model is measured by a multi coordinate measuring head, and the machining program is automatically compiled based on the measured information. The production efficiency is higher than manual grinding, and the machining accuracy and efficiency are both higher. High precision mirror polishing machine can be used for various types of aviation blades of gas turbine blades, which can polish difficult to machine titanium alloy blades and improve their surface quality.